GRAXX – respected Polish producer of excavator buckets!

GRAXX excavator buckets can be used with various brands of excavators up to 85 tons.

Buckets suit the following applications:

- trenches ["KS" Backhoe Buckets and "GS" Digging Buckets]

- sloping [Slope Buckets]

- channel excavation, e.g. digging and restoration of land drainage channels [Trapezoidal [Cable] Buckets]

- handling of stone, debris, coarse aggregate [Openwork Buckets, also referred to as Sorting Buckets]

- loading palletized materials [Pallet Forks], and initial disintegration of ground [Rippers]

GRAXX excavator buckets can be additionally equipped with mechanical or hydraulic quick couplers. GRAXX offers two types of quick couplers: S-type (S30, S40, S50, S60, S70, S80 etc.) and CW type (CW45, CW45S, CW55, CW55S etc.), matching all-purpose brackets available on the market. [More on quick couplers — click this link].

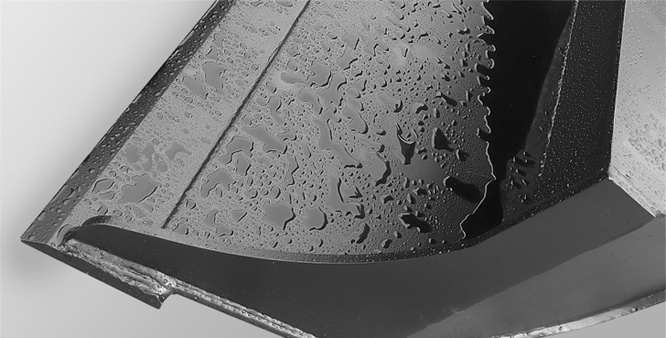

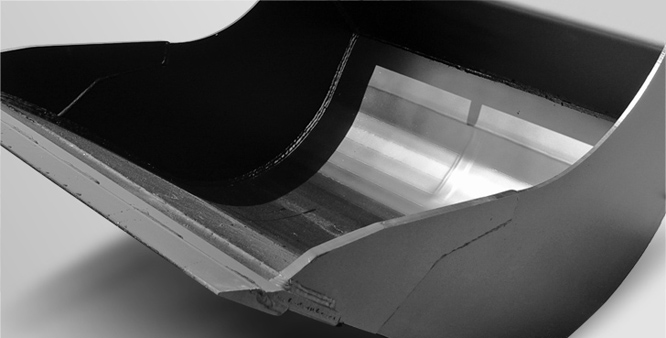

Excavator buckets are made using welding technology with mounted coupling components (the brackets). The jacket (bottom) of the scoop is made of structural steel (buckets for excavators of up to 14 tons) or HARDOX 450 HB steel (buckets for 14 ton+ excavators) and reinforced with additional flat bars. Steel sides of the scoop are reinforced at the front with HARDOX 450 HB components (buckets for 14 ton+ excavators). The blade is made of steel with a hardness of about 500 HB (standard 470–540 HB).

GRAXX excavator buckets — technical specification

|

Parameter |

Descriptions |

|

Type of equipment |

Excavator bucket, ripper, or fork carriage |

|

Power supply |

Excavator hydraulics |

|

Models |

GRT / GS / KS / PFS / PG / PS / RPS / SPS / TRS / RTPS / TPS |

|

Structure |

Steel, welded, reinforcements made of steel with an increased hardness |

|

Excavator fixture types |

S / MH /FL45 / CW |

|

Working element |

|

|

Operation |

1 person |

|

Dimensions |

See manufacturer’s catalogue |

|

Unladen mass |

See manufacturer’s catalogue |

|

Capacity |

See manufacturer’s catalogue |